PUF Indoor Tennis Court Manufacturing

PUF Indoor Tennis Court Manufacturing: Innovative Solutions for Modern Sports Facilities

Introduction to Indoor Tennis Court Construction

Indoor tennis courts epitomize a significant investment in cutting-edge sports infrastructure, providing unparalleled year-round playing opportunities and exceptional athletic experiences. As a pioneering PUF (Polyurethane Foam) indoor tennis court manufacturer, we possess an intricate understanding of the critical elements that elevate a basic space into a world-class tennis facility, setting new standards in the industry…

Key SEO Keywords

- PUF indoor tennis court

- Indoor tennis facility construction

- Sports facility manufacturing

- Tennis court design

- Indoor sports infrastructure

Understanding PUF Indoor Tennis Court Manufacturing

Structural Considerations for Indoor Tennis Courts

Indoor tennis court construction involves multiple critical components that ensure optimal performance and player satisfaction:

Structural FrameworkSteel-frame construction

- Air-supported structures

- Fabric-based designs Facilities must consider various structural options to meet specific needs and budget constraints

Essential Design ElementsFull 120’ court length - Minimum 18’ spacing between courts

Ceiling heights:

Eave height: At least 18’

4. Peak height: Minimum 36’

5. Uncluttered overhead area

6. Uniform, glare-free lighting

Cost Factors in Indoor Tennis Court Construction

Investing in an indoor tennis court involves comprehensive financial planning:

Major Cost Components

- Foundation and framework

- Roofing and wall systems

- Flooring materials

- Lighting and electrical work

- HVAC systems

- Permits and inspections Costs can vary significantly based on specific project requirements and chosen materials

Technological Innovations in PUF Indoor Tennis Court Manufacturing

Surface Technology

Modern PUF indoor tennis courts incorporate advanced surface technologies that provide:

- Enhanced player comfort

- Improved shock absorption

- Consistent playing conditions

- Durability and low maintenance

Sustainability Considerations

- Eco-friendly manufacturing processes

- Energy-efficient design

- Recyclable materials

- Reduced carbon footprint

Choosing the Right PUF Indoor Tennis Court Manufacturer

Critical Selection Criteria

Technical ExpertiseProven track record in sports facility construction

7. Advanced manufacturing capabilities

8. Compliance with international standards

Customization OptionsTailored court designs

9. Adaptable to various space constraints

10. Multiple surface options

Technical Support

Comprehensive installation services

11. Ongoing maintenance guidance

12. Performance optimization consulting

Industry Certifications and Quality Assurance

Reputable PUF indoor tennis court manufacturers should possess:

- ISO 9001 certification

- Sports facility engineering credentials

- Proven performance metrics Certifications demonstrate commitment to quality and customer satisfaction

Conclusion: Investing in Excellence

An expertly manufactured PUF indoor tennis court is more than just a playing surface—it’s a comprehensive sports solution that enhances athletic performance, provides year-round training opportunities, and represents a strategic investment in sports infrastructure.

Ready to Transform Your Sports Facility?

Contact our expert team to discuss your indoor tennis court project. We’ll help you create a world-class facility that meets your specific requirements and exceeds expectations.

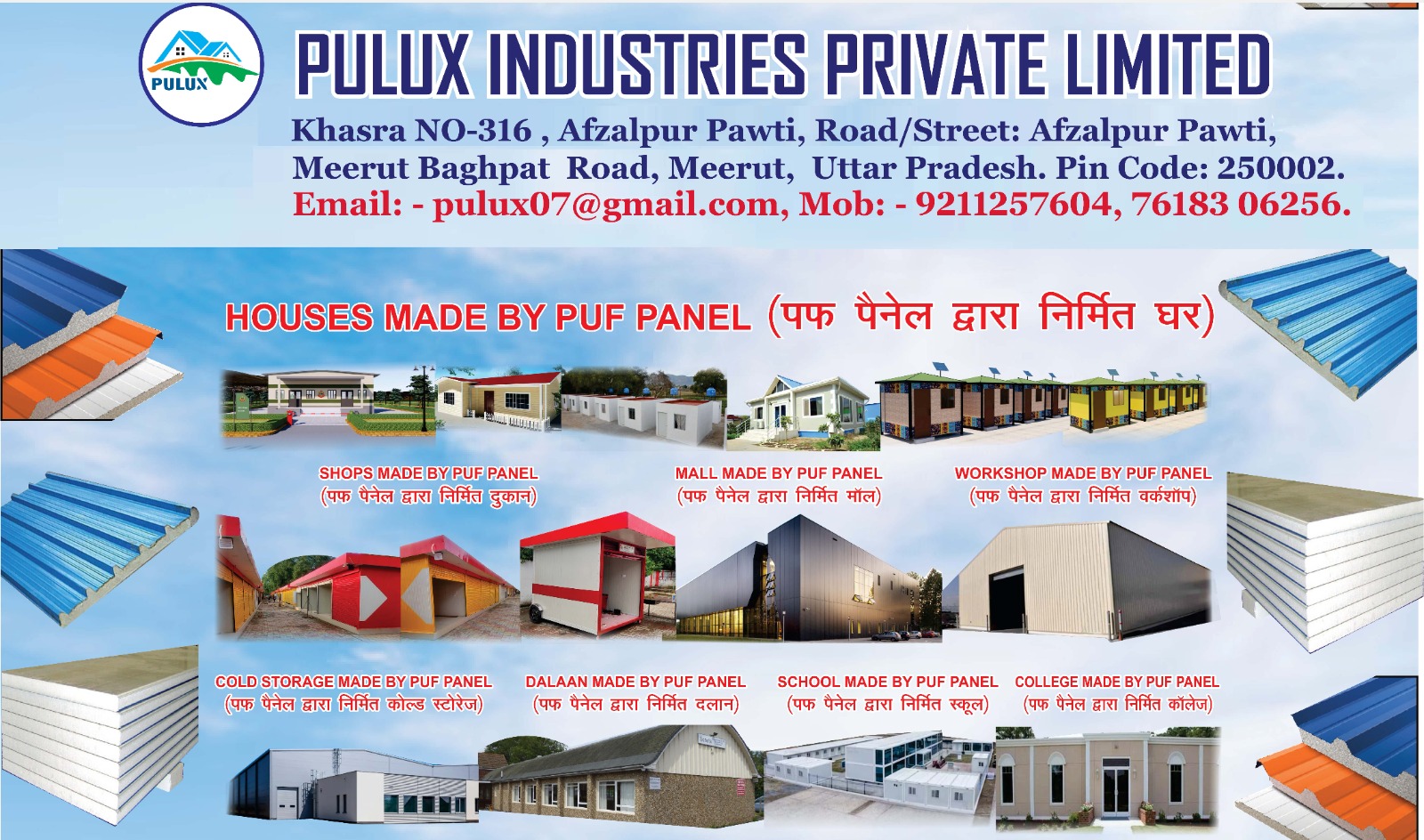

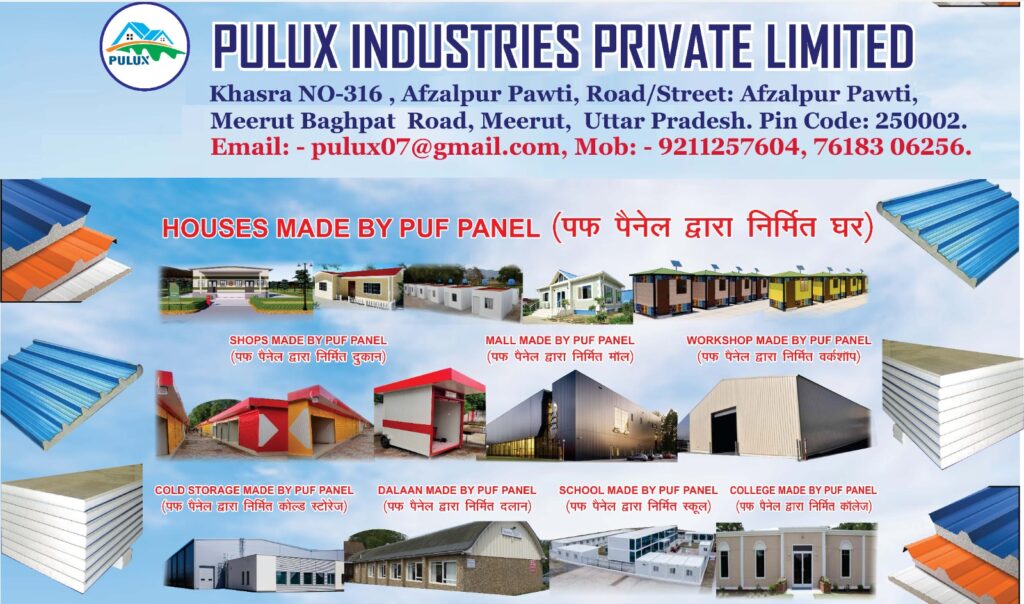

Contact Information

- Phone: +91 7618306256, +91 9211257604

- Email: info@puluxindustries.com

- Website: www.puluxindustries.com

Keywords: PUF indoor tennis court, indoor tennis facility, sports infrastructure, tennis court manufacturing, athletic facility design

Products

- Our Products

- PUF Sandwich Panels

- PUF Cold Rooms

- PUF Industrial Sheds

- PUF Cold Storage Units

- PUF Indoor Tennis Court

- PUF Labor Huts

- PUF Banana Ripening Chambers

- PUF Warehouses

- PUF Mass Camp Houses

- PUF Factory sheds